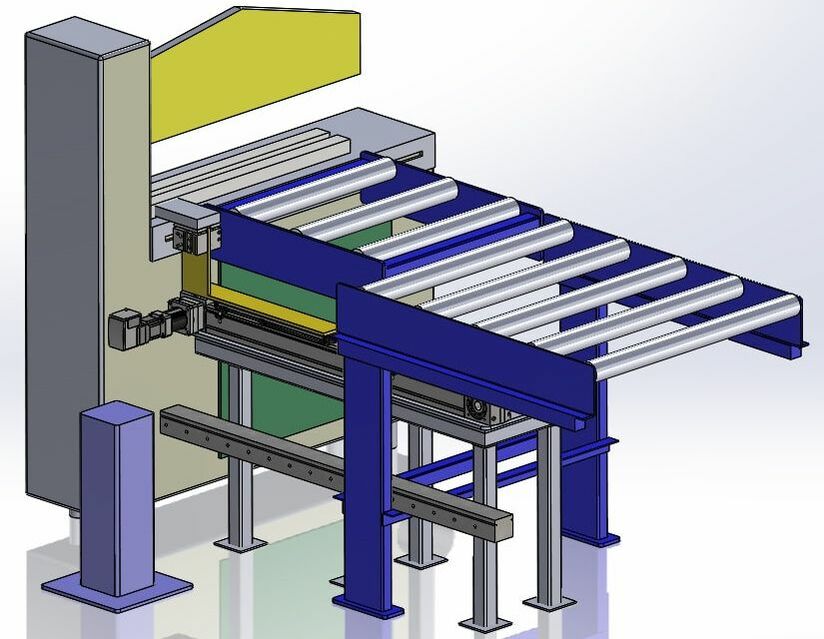

Retrofitting - Keep your machines going

When automation components become obsolete, failures are more likely, maintenance costs are rising and the up-time can't be guaranteed anymore.

To ensure your long-term success, it’s possible to upgrade and retrofit the existing controls. This results in a state-of-the- art equipment, which meets the latest safety requirements and is ready for your industry 4.0 factory of the future.

To ensure your long-term success, it’s possible to upgrade and retrofit the existing controls. This results in a state-of-the- art equipment, which meets the latest safety requirements and is ready for your industry 4.0 factory of the future.

Upgrading - adding a functionality

Process requirements change over time, but instead of investing in a new machine, it is worth looking into the option of adjusting your existing equipment. If it technically possible, why not add an extra functionality to the machinery your operators already know?

repair and preventive services

In industry, all unscheduled downtime for machines or plants must be resolved as quickly as possible. Whenever a breakdown occurs, we assist you on site with troubleshooting, repair and maintenance.

Based on our long experience we can support in case of problems on:

Based on our long experience we can support in case of problems on:

- mechanics

- pneumatic and hydraulics

- electrical installations

- PLC & PC based automation

- Servodrives and positioning systems

- Numeric controls for CNC machines